Brexit

What’s the Brexit status?

In the nick of time the UK concluded a deal with the EU. As many details are still unclear, please contact us if you require insights or explanation. We submit each case to our in-house customs- and fiscal experts. This way we can assist you in finding the most optimal transport and/or storage solution.

How can we help you?

All our warehouses in Belgium are bonded warehouses, which are in custom approved zones. Objects can be stored in transit and are not subject to import duties and/or VAT. The other way around, in these warehouses we can also store objects with a free circulation status (VAT paid) and they keep their free circulation status in the EU.

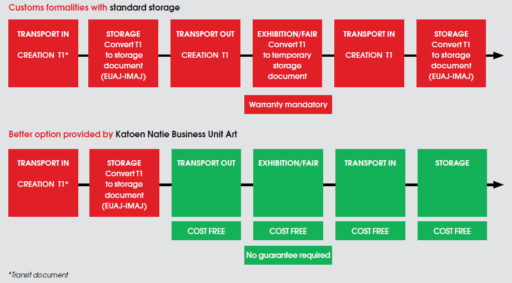

Katoen Natie has a unique position. Only at Katoen Natie are you allowed to remove art objects from these warehouses (e.g. for an exhibition or trade fair) while the objects remain bonded.

This means that the objects can travel throughout the EU free from import duties and/or VAT, to exhibitions and fairs, without any additional administration, guarantees or costs applying. The administration and cost structure surrounding the movement of your art are simplified/reduced to a minimum.

The simplicity of our set-up is explained in the graphic below:

Why store at Katoen Natie?

When you store your art collection in our depots, you can be sure that your objects can still easily travel the EU. This applies to both objects subjected to customs and objects which have the EU’s free circulation status, while saving you unnecessary costs and headaches.

Furthermore, we store your objects in world class facilities. We offer more than +250.000 sqft of art storage, which is:

- Hypersecure (INCERT3)

- Ecological (powered by wind mills & solar panels)

- Discrete and anonymous

- Climatized (ranging from ASHRAE AA+ to ASHRAE AA)

- ISO9001-2015 certified

- Inspected by all major Insurance players

- Competitively priced

- Situated in the heart of EU, close to major airport/seaport/transport hubs

- Private vaults or grouped storage

- Supported by an in house developed collection management system

Katoen Natie is a one-stop-shop, offering all services expected from a professional art logistics player, including art collection management, fine art transport, viewing/sales rooms, condition checks, photography, expo rooms, packaging, installation, courier services, …

Want to know more?

Get in touch with us to discuss your questions about Brexit, art transport or art storage. We already work with company collections, artists estates, museums, international collectors & galleries, foundations, … so chances are we can answer your particular questions with answers stemming from experience.

Please contact us at: ktn.art@katoennatie.com

Katoen Natie and Intergamma Unveil Innovative AutoStore Solution

Partnership between Katoen Natie and Intergamma leads to a new storage and picking system with round the clock robots.

Katoen Natie and Intergamma are now utilizing AutoStore, the world’s fastest and most reliable order processing system per square meter, for e-commerce order deliveries to Intergamma’s customers.

This cube-shaped automated system, comprising approximately 900 m³ and equipped with 20 robots, has been in operation since the end of September 2023 at Katoen Natie’s logistics platform in Kallo, which is the largest “multi-customer” logistics platform in Europe. The installation and implementation are part of a joint future project between Katoen Natie and Intergamma, following the recent extension of their successful 10-year partnership by an additional 5 years. For Intergamma, the Benelux leader in the DIY market and currently in a strong growth phase, this means that all its e-commerce products can reach private consumers even faster and more efficiently. “For Katoen Natie, the expertise built with AutoStore is an additional incentive to attract new customers to our logistics platforms with innovative solutions,” says Fernand Huts, Chairman of Katoen Natie.

Katoen Natie is implementing this goods-to-man automated storage and picking system for the first time at its Kallo logistics platform. This implementation is part of the shared desire of Katoen Natie and Intergamma to ensure they can continue to work together in a future-proof manner. Katoen Natie Engineering Solutions, Katoen Natie’s in-house research department, is closely monitoring the process and operations, and is also exploring the opportunity to invest in additional AutoStore installations on other logistics platforms.

Intergamma in a Growth Phase

In the Benelux, Intergamma is the market leader in the DIY industry with three brands: GAMMA Netherlands, GAMMA Belgium, and Karwei, which together operate 384 stores in Belgium and the Netherlands. “Ongoing developments in Intergamma’s online channels have led to increased volumes,” says Joost De Beijer, CEO of Intergamma. “The new investment in AutoStore in collaboration with Katoen Natie aligns perfectly with our strategy, in which e-commerce will continue to be crucial in the future while we simultaneously make our supply chain more sustainable. We aim to evolve into a ‘one-stop shop,’ where consumers can turn to GAMMA and Karwei to address their entire DIY project in one go and have their supplies delivered or picked up wherever they prefer.” Intergamma expects that the investment will ultimately lead to increased capacity, flexibility, better reliability, and lower costs.

How Does AutoStore Work?

Bins with inventory are stacked 16 levels high next to and on top of each other within the grid. The grid is the customized aluminum rail system surrounding the bins and robots. Autonomous robots travel on top of the grid and continuously collaborate to retrieve stock for orders from the grid. They do this by lifting bins from the grid and rearranging them until they have the correct one. This bin is then presented at one of the 3 picking stations. The picker retrieves the goods from the bin and processes the order. The bin is returned to the grid. The algorithm ensures that stock for orders is always retrieved in the most efficient manner. This automation has no impact on existing jobs, as the pickers can now accomplish more with the same team. Additionally, it reduces picking errors, ensures continuous inventory management, optimal availability, and no single point of failure.

Round the clock robots

Customers can place orders online until 9:00 PM, and Katoen Natie hands over the packages to the carrier by 11:00 PM, ensuring that the packages are delivered to the customer’s doorstep the next day. While Katoen Natie sleeps at night, the robots keep working. During the night, they ensure that the fast-moving products of Intergamma are always located in the top “drawers” of the grid and are thus picked up the fastest. All e-commerce orders for Intergamma are transmitted directly to AutoStore through the Electronic Data Interchange (EDI) electronic data exchange system. AutoStore is also connected to Katoen Natie’s existing packing automation. As a result, each box is automatically sealed after picking and is not touched until it is loaded.

Since September 25, a significant portion of Intergamma’s products has been picked by AutoStore robots at Katoen Natie. However, starting from the end of October, the planned stock of Intergamma will also be stored in AutoStore. This will include more than 21,000 items distributed across 31,000 bins, with 6,528 of them subdivided into 4 compartments, bringing the total to 50,584 locations with stock.

Our Autostore in action on YouTube: Click Here

Elevating E-commerce with Personalized Rematerialization Solutions

In today’s dynamic e-commerce landscape, customer experience reigns supreme. However, challenges arise when a physical product isn’t readily available to fulfill an online order. Katoen Natie is committed to providing innovative solutions that empower our clients to conquer these challenges. This article discusses how we co-created a rematerialization solution to bridge the gap between digital and physical fulfillment.

Understanding Rematerialization

Rematerialization is the process of creating physical products from digital assets. This innovative approach allows businesses to fulfill orders even when the physical items are not in stock. By converting digital designs, images, and personalized messages into tangible products,

The Challenge: Delivering the Digital as Physical

Consider a customer purchasing a unique gift box online. Traditionally, such a box might not be readily stocked in warehouses due to its limited sales volume, leading to delays and frustration. Our rematerialization process addresses this challenge by creating the desired product on demand.

Our Innovative Approach

We leverage our expertise to transform digital assets into physical deliverables. Here’s how it works:

- Order Recognition: Our intelligent systems identify orders containing rematerialization requests.

- Digital Asset Retrieval: We securely access the relevant digital assets, such as high-quality product images and personalized messages, provided by our clients.

- High-Definition Printing: Utilizing state-of-the-art printing technology, we produce high-definition replicas of the digital assets on premium materials.

- Professional Assembly: The printed materials are carefully assembled into a visually appealing and informative package, ready for final packaging.

- Seamless Integration: The rematerialized elements are seamlessly integrated with the rest of the order, ensuring efficient delivery.

Benefits for Our Customers

Our rematerialization solution offers numerous advantages:

- Enhanced Customer Experience: Deliver a unique and memorable experience by fulfilling orders with both physical and digital components.

- Reduced Inventory Costs: Eliminate the need to stock slow-moving physical goods, reducing storage requirements and associated costs.

- Increased Agility: Respond rapidly to changing market demands and offer a wider variety of products without inventory constraints.

- Sustainability: Minimize waste by printing only what’s needed, reducing the environmental impact of your operations.

Beyond Rematerialization: Partnering for Success

Our rematerialization process is just one example of Katoen Natie’s commitment to providing innovative Value Added Services solutions. We believe in fostering long-term partnerships with our clients. We work collaboratively to understand your unique challenges and develop customized solutions that drive efficiency, reduce costs, and enhance customer satisfaction.

Experience the Katoen Natie Difference

With our innovative rematerialization solutions, Katoen Natie is helping businesses elevate their e-commerce operations. By integrating digital and physical fulfillment seamlessly, we ensure that your customers receive the best possible experience.

Curious to elevate your e-commerce operations, reach out to us and speak with an expert today.